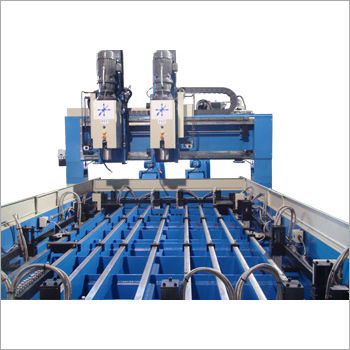

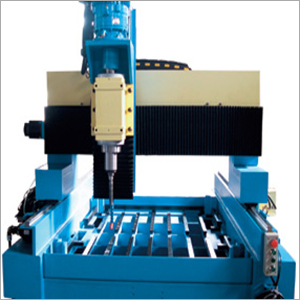

Gantry Type CNC Drilling Machine With Servo Feeding

Product Details:

70000.00 - 95000.00 USD ($)/Set

X

Gantry Type CNC Drilling Machine With Servo Feeding Price And Quantity

- 1 Set

- 70000.00 - 95000.00 USD ($)/Set

Gantry Type CNC Drilling Machine With Servo Feeding Trade Information

- Taichung Taiwan

- 5-10 Set Per Month

- 7 Days

- Export Packaging

- All India

Product Description

Specification:

| Capacity | Hole Diameter mm | 14 - 50 |

| Tap | M6 - M32 | |

| Long Hole | 14x - 32x mm(unlimited) | |

| Max. Works Size | 1000x1500 mm | |

| Work Area | 4 | |

| Thickness | Total Thickness 100 mm (Vice Stroke 105 mm) | |

| Hydraulic | 50 kg/cm2 (Max. 70 kg/cm2) | |

| Coolant | Water bass collant, Electric Pump | |

| Chip Conveyor | Electric Conveyor | |

| Spindle Motor | 5.5 KW | |

| Spindle | Drill | 1 |

| Shank | BT-40 | |

| Speed control | Inverter Control | |

| RPM | 150 -- 560 | |

| Drill Length | 100 -- 470 | |

| Positioning | X Stroke | 1000 mm |

| X Speed | 9 m/min | |

| X Drive | Servo Motor + Rolling-Ball Bolt | |

| Y Stroke | 1500 mm | |

| Y Speed | 9 m/min | |

| Y Drive | Servo Motor + Ball Screw | |

| Z Stroke | 400 mm | |

| Z Speed | 5 m/min | |

| Z Drive | Servo Motor + Ball bolt | |

| Clamps | Method | Hydraulic clamped |

| Quantity Hydraulic | 8 | |

| Quantity Manual | 8 | |

| Dimension | Force | 600 kg |

| Work stand Height | App. 800 mm | |

| L x W x H mm | -- | |

| Weight | 5000 kg | |

| NC Devices | Screen | Human-Machine Interaction (touch-controlled) attached with A screen to a industrial computer |

| Servo Axis | 3 | |

| Memory Capacity | 100 sets CF card, unlimited when attached with a industrial computer | |

| Min. Setting Unit | 0.01 mm | |

| Programming | Multi-pattern process-dialogue inputting/ cross laser teaching/ files Transferred by DXF when equipped with an industrial computer | |

| Ax. Program | 1 home point mixed with 10 programs | |

| Re-positioning | Machine continues auto operation from any position | |

| Cutting Condition | Cutting condition (life, loading ratio, revolutions, feeding capacity, Feeding time, penetration capacity) may input by hand | |

| Fine Adjustment | Revolutions & feeding capacity may fine adjust 50 percent | |

| Signal Lamp | 3 colors (red, yellow, green) signal lamps | |

| Tapping | Tapping M6 - M32 | |

| Long Hole Milling | 14 mm x -- 32 mm x | |

| Marking | To mark center and verify the program | |

| Home Points | 4 home points, expanded to 8 home points (optional) |

Enter Buying Requirement Details