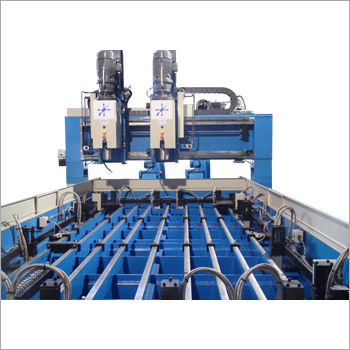

Double Spindles Gantry Type Drilling Machine

Product Details:

105000.00 - 135000.00 USD ($)/Set

X

Double Spindles Gantry Type Drilling Machine Price And Quantity

- 1 Set

- 105000.00 - 135000.00 USD ($)/Set

Double Spindles Gantry Type Drilling Machine Trade Information

- Taichung Taiwan

- 5-10 Set Per Month

- 7 Days

- Export Packaging

- Australia Central America South America Western Europe Middle East Eastern Europe Asia North America Africa

- All India

Product Description

A double spindles gantry type drilling machine is a type of drilling machine that is designed with two drilling spindles mounted on a gantry structure. This design allows for the drilling of multiple holes simultaneously, which can increase productivity and efficiency. The gantry structure provides stability and precision while the double spindles offer more flexibility in terms of positioning and drilling depth. It is commonly used in industries such as aerospace, automotive, and construction for drilling holes in large and complex workpieces. They are known for their speed, accuracy, and ability to handle heavy-duty drilling operations.

Double Spindles Gantry Type Drilling Machine Specifications:

- Model: DNA-2035H

- Two spindles with X axis independent control.

- Work area: 2000 x 3500 mm

- Hole Diameter: 14 to 40 mm

- With chip conveyor

Frequently Asked Questions:

1. What is a double spindles gantry type drilling machine?

Ans - A double spindles gantry type drilling machine is a type of drilling machine that features two spindles for drilling two holes simultaneously. It has a gantry design, meaning that the drilling head is mounted on a bridge-like structure that spans the workspace. This design allows for greater precision and stability in drilling operations.

2. What are the advantages of a double spindles gantry type drilling machine?

Ans - Some advantages of a double spindles gantry type drilling machine include:

- The ability to drill two holes simultaneously, which increases productivity and reduces cycle time.

- A gantry design that allows for greater precision and stability in drilling operations.

- The ability to drill holes in different positions and angles.

- High accuracy and precision in drilling operations.

- Easy maintenance and low operating costs.

3. What types of materials can a double spindles gantry type drilling machine drill?

Ans - A double spindles gantry type drilling machine can drill a wide range of materials, including metals, plastics, composites, and wood.

4. What is the maximum drilling capacity of a double spindles gantry type drilling machine?

Ans - The maximum drilling capacity of a double spindles gantry type drilling machine depends on the specific model and manufacturer. Generally, these machines can drill holes with a diameter ranging from a few millimeters to several centimeters.

5. What are some safety precautions to take when using a double spindles gantry type drilling machine?

Ans - Some safety precautions to take when using a double spindles gantry type drilling machine include:

- Always wear appropriate personal protective equipment, such as safety glasses and ear protection.

- Ensure that the workpiece is securely clamped and properly positioned before drilling.

- Avoid wearing loose clothing or jewelry that could get caught in the machine.

- Keep the machine clean and well-maintained to prevent accidents.

- Follow all manufacturer instructions and guidelines for safe operation of the machine.

6. What maintenance is required for a double spindles gantry type drilling machine?

Ans - Regular maintenance is important to keep a double spindles gantry type drilling machine running smoothly and efficiently. Some maintenance tasks may include:

- Regular cleaning of the machine to remove debris and prevent buildup.

- Lubrication of moving parts to prevent wear and reduce friction.

- Checking and tightening bolts and screws to ensure that the machine is properly assembled.

- Regular inspection of the machine for signs of wear or damage.

- Replacing worn or damaged parts as needed.

- Following all manufacturer guidelines and instructions for maintenance and upkeep of the machine.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email