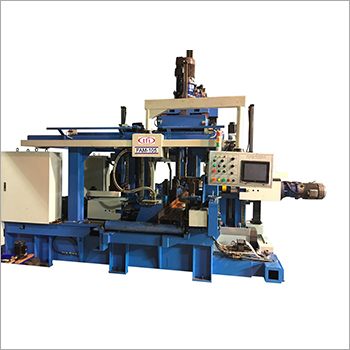

Automatic Beam Line Drilling Machine

उत्पाद विवरण:

स्वचालित बीम लाइन ड्रिलिंग मशीन मूल्य और मात्रा

- सेट/सेट्स

- सेट/सेट्स

- 1

स्वचालित बीम लाइन ड्रिलिंग मशीन व्यापार सूचना

- ताइचुंग, ताइवान

- 5-10 प्रति महीने

- 7 दिन

- मध्य अमेरिका ऑस्ट्रेलिया उत्तरी अमेरिका मिडल ईस्ट पूर्वी यूरोप दक्षिण अमेरिका एशिया पश्चिमी यूरोप अफ्रीका

- ऑल इंडिया

उत्पाद विवरण

Owing to vast market experience, we are proving a large assortment of Automatic Beam Line Drilling Machine in adherence to set the principles as well as policies of global market. This machines works smoothly to increase the life of spindle. Automatic Beam Line Drilling Machine is inserted with several functions such as dual language system, versatile software system, digital graphic pattern, advance operating hydraulic feeding, easy handling manual button etc. It helps to minimize the mistake of setting the digital program.

Specification:

| Specification / Model | FAM-105 | FAM-105 PLUS | FAM-105A PLUS | ||

| Capacity | H1000 x 500 - H150 x 75 | H1000 x 500 - H150 x 75 | H1000 x 500 - H150 x 75 | ||

| Spindles | Spindle qty | Three independent positioning spindles | Three independent positioning spindles | Three independent positioning spindles | |

| Shank type | BT40 | BT40 | BT40 | ||

| RPM control | Variable (Variable Frequency controlled) | Variable (Variable Frequency controlled) | Variable (Variable Frequency controlled) | ||

| Capacity 1 | HSS drill bit: 14 - 40 mm | HSS drill bit: 14 - 40 mm | HSS drill bit: 14 - 40 mm | ||

| Capacity 2 | HSS GOH : 16 - 32 mm | HSS GOH : 16 - 32 mm | |||

| Revolution Speed | 150 - 600 rpm, Automatic adjustment + manual fine-tuning | ||||

| Feeding speed | 0.10 - 5 mm /rev, manual fine-tuning | 0.10 - 5 mm /rev, manual fine-tuning | 0.10 - 5 mm /rev, manual fine-tuning | ||

| Feeding control | Auto feeding control, no need adjust limited switch after tool | ||||

| Tool length | 50 - 470mm | 50 - 470mm | 50 - 470mm | ||

| ACT | R spindle, H1 | 3-tools storage | |||

| U spindle, H2 | 3-tools storage | ||||

| spindle, H3 | 3-tools storage | ||||

| Drive & Positioning | Upper X Axis | Stroke | 580mm | 580mm | 580mm |

| Move speed | 7m/min | 7m/min | 7m/min | ||

| Drive | AC Servo motor + ball screw | AC Servo motor + ball screw | AC Servo motor + ball screw | ||

| Upper Y Axis | Stroke | 1000mm | 1000mm | 1000mm | |

| Move speed | 7m/min | 7m/min | 7m/min | ||

| Drive | AC Servo motor + ball screw | AC Servo motor + ball screw | AC Servo motor + ball screw | ||

| Right, Left X Axis | Stroke | 580mm | 580mm | 580mm | |

| Move speed | 7m/min | 7m/min | 7m/min | ||

| Drive | AC Servo motor + ball screw | AC Servo motor + ball screw | AC Servo motor + ball screw | ||

| Right, Left Y Axis | Stroke | 500mm | 500mm | 500mm | |

| Move speed | 7m/min | 7m/min | 7m/min | ||

| Drive | AC Servo motor + ball screw | AC Servo motor + ball screw | AC Servo motor + ball screw | ||

| Upper Feeding | Stroke | 600mm | 600mm | 600mm | |

| Move speed | 5m/min | 5m/min | 5m/min | ||

| Drive | Independent Hydraulic + Encoder | Independent Hydraulic + Encoder | Independent Hydraulic + Encoder | ||

| Right & Left Feeding | Stroke | 400mm | 400mm | 400mm | |

| Move speed | 5m/min | 5m/min | 5m/min | ||

| Drive | Independent Hydraulic + Encoder | Independent Hydraulic + Encoder | Independent Hydraulic + Encoder | ||

FAQ

1. What is a machine for automatically drilling beam lines?

Ans - An automated machine tool that is used to cut and drill holes into beam profiles and other structural elements is known as an automatic beam line drilling machine. It has the ability to load cutting tools, automatically position the workpiece, and regulate the cutting process' speed and feed.

2. Why is utilising an automatic beam line drilling machine advantageous?

Ans - The use of an automatic beam line drilling machine has higher precision, higher production rates, and improved safety as its key benefits. The workpiece may be positioned precisely by the machine, which removes the possibility of human error. The machine can also be designed to drill several holes accurately and fast in a single pass, which lowers production time.

3. What parts are included in an automatic beam line drilling machine?

Ans - A workpiece holder, a workpiece positioning system, a control system, and a cutting tool spindle are commonly included in an automatic beam line drilling machine. Other parts, such a coolant delivery system and a dust collection system, might also be incorporated, depending on the model.

4. What kinds of materials can an automatic beam line drilling machine handle?

Ans - A broad variety of materials, such as aluminium, steel, copper, brass, and other materials frequently used in structural components, can be processed by an automatic beam line drilling machine.

5. How long does it typically take for an automatic beam line drilling machine to be delivered?

Ans - An automatic beam line drilling machine's lead time is typically influenced by the manufacturer and model. Depending on the intricacy of the equipment and the availability of parts, lead times can range from a few weeks to a few months.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+