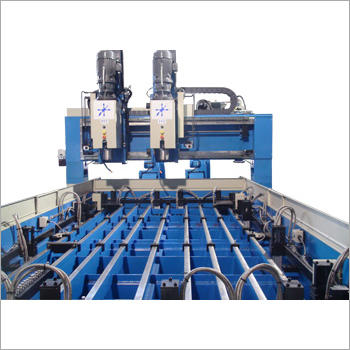

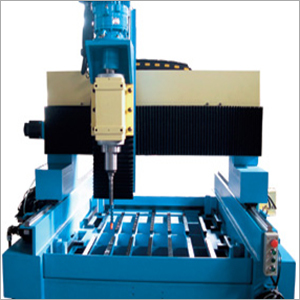

Automatic Gantry Type Drilling Machine

Product Details:

75000.00 - 95000.00 USD ($)/Set

X

Automatic Gantry Type Drilling Machine Price And Quantity

- 75000.00 - 95000.00 USD ($)/Set

- 1 Set

Automatic Gantry Type Drilling Machine Trade Information

- Taichung Taiwan

- 5-10 Set Per Month

- 7 Days

- Export Packaging

- All India

Product Description

An automatic gantry type drilling machine is a piece of equipment that is used to drill holes in large, heavy parts or materials, such as metal plates, beams, and other structural components. The machine is designed to be operated automatically and is capable of drilling multiple holes in a single workpiece with precision and accuracy.

The gantry type drilling machine consists of a large, sturdy frame, or gantry, which supports the drilling head and the workpiece. The drilling head is typically equipped with a range of drilling tools, including drills of various sizes and shapes, as well as other cutting tools. The machine operates using a computer numerical control (CNC) system, which allows the operator to program the machine with the desired drilling pattern and specifications. The CNC system then controls the movement of the drilling head, as well as the speed and feed rate of the drilling tools, to ensure that each hole is drilled to the correct depth and diameter.

The automatic gantry type drilling machine is commonly used in the manufacturing and construction industries for drilling holes in large parts, such as bridge components, shipbuilding, wind turbine components, and other structural elements. The machine is designed to be highly efficient and accurate, reducing the need for manual labor and increasing productivity.

Automatic Gantry Type Drilling Machine Features:

The following are some of the features of an automatic gantry type drilling machine:

1. High Precision: The automatic gantry type drilling machine is designed to achieve high precision and accuracy in drilling holes. It is equipped with a CNC system that controls the movement of the drilling head and ensures that each hole is drilled to the correct depth and diameter.

2. High Efficiency: The machine is capable of drilling multiple holes in a single workpiece, making it highly efficient and productive. It can drill holes of various sizes and shapes in a range of materials, including metal plates, beams, and other structural components.

3. Large Working Area: The machine has a large working area, which allows it to handle large parts and materials. It is designed to accommodate workpieces of different sizes and shapes, making it versatile and flexible.

4. Automatic Operation: The automatic gantry type drilling machine is designed to operate automatically, reducing the need for manual labor and increasing productivity. The CNC system allows the operator to program the machine with the desired drilling pattern and specifications, and the machine takes care of the rest.

5. Safety Features: The machine is equipped with various safety features, including emergency stop buttons, safety guards, and interlocks, to ensure the safety of the operator and other workers.

6. User-Friendly Interface: The machine is designed to be user-friendly, with an intuitive interface that allows the operator to easily program and control the machine.

7. Durable and Reliable: The machine is built to be durable and reliable, with high-quality components and a sturdy frame that can withstand the rigors of heavy use.

Overall, the automatic gantry type drilling machine is a versatile and efficient piece of equipment that is essential for many manufacturing and construction applications.

Automatic Gantry Type Drilling Machine Applications:

The automatic gantry type drilling machine is used in various industries for drilling holes in large and heavy workpieces. Some of the common applications of the machine are:

1. Manufacturing Industry: The machine is widely used in the manufacturing industry for drilling holes in large metal parts and components such as structural steel, machine components, and aerospace components.

2. Construction Industry: The machine is also used in the construction industry for drilling holes in large steel beams, girders, and other structural elements used in buildings, bridges, and other infrastructure projects.

3. Wind Energy Industry: The machine is used in the wind energy industry for drilling holes in wind turbine components such as tower sections, rotor blades, and nacelles.

4. Shipbuilding Industry: The machine is used in the shipbuilding industry for drilling holes in ship components such as hulls, bulkheads, and decks.

5. Automotive Industry: The machine is used in the automotive industry for drilling holes in car frames, chassis, and other structural components.

6. Railway Industry: The machine is used in the railway industry for drilling holes in railway tracks, bridges, and other structures.

Overall, the automatic gantry type drilling machine is an essential tool for industries that require drilling holes in large and heavy workpieces with high precision and efficiency.

Frequently Asked Questions:

1. What is an automatic gantry type drilling machine?

Ans: An automatic gantry type drilling machine is a piece of equipment that is used to drill holes in large, heavy parts or materials, such as metal plates, beams, and other structural components. The machine is designed to be operated automatically and is capable of drilling multiple holes in a single workpiece with precision and accuracy.

2. What are the features of an automatic gantry type drilling machine?

Ans: The features of an automatic gantry type drilling machine include high precision, high efficiency, a large working area, automatic operation, safety features, a user-friendly interface, and durability and reliability.

3. What are the applications of an automatic gantry type drilling machine?

Ans: The applications of an automatic gantry type drilling machine include manufacturing, construction, wind energy, shipbuilding, automotive, and railway industries.

4. How does an automatic gantry type drilling machine work?

Ans: The machine operates using a computer numerical control (CNC) system, which allows the operator to program the machine with the desired drilling pattern and specifications. The CNC system then controls the movement of the drilling head, as well as the speed and feed rate of the drilling tools, to ensure that each hole is drilled to the correct depth and diameter.

5. What are the advantages of using an automatic gantry type drilling machine?

Ans: The advantages of using an automatic gantry type drilling machine include increased productivity, higher accuracy and precision, reduced labor costs, and improved safety for workers. The machine can also handle large and heavy workpieces, making it a versatile and valuable tool for many industries.

Enter Buying Requirement Details